Wire Sawing Indoors Without Heavy Equipment

How We Segment Thick Reinforced Concrete for Safe Haul-Out in Limited-Access, Sensitive Sites

Abstract

Indoor controlled demolition fails most often after the cut — during handling, haul-out, dust/slurry management, and schedule windows. In sensitive environments (banks, active residential buildings, operating plants, transit/metro stations, tunnels and high-rise foundation interfaces), “just break it out with a hammer and machine” is frequently not an option. The alternative is a segmented removal plan: wire sawing (or track/wall saws where applicable), combined with a logistics-first grid, verified embed conditions, controlled slurry capture, and defined pick/roll paths. This article presents an engineering approach to indoor wire sawing without excavators/mini-excavators with breakers, focusing on segmentation math, wire wear economics, water/slurry control, and risk controls that matter to estimators and engineers.

1) What “without heavy equipment” actually means (in this context)

Definition: “Without heavy equipment” here means no excavator or mini-excavator with a hydraulic breaker inside the building (i.e., no impact-dominant demolition method).

Allowed support methods may include (site-dependent): pallet jacks, dollies, skates, chain falls/hoists, winches, overhead cranes (crane beams), and sometimes forklifts/skid steers if access and floor capacity allow.

Why this definition matters: it forces the demolition plan to be constrained by (1) vibration, (2) airborne silica dust, (3) noise, (4) time windows, and (5) haul-out geometry — not by “tool horsepower.”

2) Why impact demolition becomes a compliance and schedule problem indoors

Indoor demolition is rarely “just demolition.” In active environments it becomes exposure control + disruption control + logistics control.

2.1 Respirable crystalline silica: the non-negotiable exposure driver

Concrete cutting/breaking can generate respirable crystalline silica, a well-documented hazard requiring strict control via wet methods, ventilation, isolation, and work practices. OSHA’s silica rule sets a PEL of 50 μg/m³ as an 8-hour TWA (and an action level of 25 μg/m³).

In Ontario, respirable crystalline silica exposure limits are governed under provincial frameworks (e.g., Regulation 833 exposure limits listings and related guidance).

What matters operationally: controlling dust is not a “nice to have”; it is often the difference between staying on the job and getting stopped.

2.2 Wet cutting is not theory — it is measurable reduction

Field and lab work consistently shows large exposure reductions when water is properly applied. In head-to-head tests cutting reinforced concrete pipe, wet cutting reduced respirable silica concentration by ~85% in reported results.

Literature reviews/engineering control studies also report reductions of at least ~90% for certain cutting tasks when water suppression is correctly implemented.

NIOSH guidance likewise emphasizes water sprays as a primary engineering control for dust suppression.

Implication for indoor work: wet methods shift the problem from airborne dust to water/slurry containment — which is manageable if planned.

2.3 Noise: indoor sites often have strict tolerances (and legal exposure limits)

Noise is both an occupational exposure issue and a site-operations issue. Ontario’s noise regulation and guidance commonly reference 85 dBA Lex,8 as the exposure limit for workers.

NIOSH recommends 85 dBA over an 8-hour shift and uses a 3 dB exchange rate (each +3 dB halves permissible exposure time).

Real equipment numbers matter: Ontario guidance lists jackhammers at ~100–115 dBA, and concrete saws around ~97–103 dBA (typical ranges).

Estimator takeaway: impact demolition can instantly put you in high-noise territory with very short allowable exposure durations — especially in enclosed or reflective spaces.

2.4 Vibration: it is not only “comfort” — it’s risk and productivity

For hand-arm vibration, common reference values used internationally include an exposure action value (EAV) of 2.5 m/s² A(8) and an exposure limit value (ELV) of 5.0 m/s² A(8).

Typical hand-arm vibration magnitudes for mounted roadbreakers are cited in ranges like ~5–20 m/s² (average around 12 m/s²), meaning EAV/ELV can be reached quickly depending on task duration.

Ontario also provides practical hand-arm vibration guidance for employers.

Why wire sawing helps: wire sawing is not vibration-free, but it avoids an impact-dominant mechanism — which is often what sensitive sites explicitly prohibit.

3) The core engineering idea: segmentation is the project

Wire sawing is a cutting method. Indoor controlled demolition is a segmentation + handling system.

3.1 The mass calculation that prevents “beautiful cuts that can’t be moved”

We size segments using first-principles volume and unit weight:

Segment mass (kg) = Volume (m³) × Density (kg/m³)

For normalweight concrete, density commonly falls around ~2240–2400 kg/m³ (140–150 lb/ft³).

In field planning, we often use a conservative ~2500 kg/m³ for reinforced concrete to avoid underestimating weight.

Example (typical indoor grid):

- Plan size: 3 ft × 3 ft (0.914 m × 0.914 m)

- Thickness: 300 mm (0.30 m)

- Volume: 0.914 × 0.914 × 0.30 ≈ 0.251 m³

- Mass (using 2500 kg/m³): 0.251 × 2500 ≈ 628 kg

This lands directly in a practical “manageable segment” zone for many indoor handling setups (depending on pick method and route constraints).

3.2 Segment size is a balance of five constraints

We do not select segment size from one variable. We select it from a constraint set:

1) Haul-out geometry: doors, corridors, turns, elevators, ramps.

If you cannot physically pass the segment through the tightest point, the cut plan is wrong.

2) Pick method and attachment:

- chemical anchors + lifting eyes

- through-cores for shackles/straps

- forklift/skid steer forks (if permitted)

- chain fall / winch

- overhead crane beam

Pick points must match segment mass and rebar/embedded steel realities.

3) Floor capacity and contact pressure:

Even if total weight is acceptable, point loading from dollies/skates or forks can exceed local slab capacity. You either distribute load (plates/mats) or reduce segment mass.

4) Staging footprint:

Segments take space. Indoor sites are often staging-limited. If you cannot stage safely without blocking operations, you must change the grid and sequence.

5) Economics of cuts:

More cuts = more wire wear + more setup + more water + more slurry handling. “Smaller is safer” is true only until it becomes economically irrational.

Practical rule: the “best” segmentation grid is the cheapest grid that still guarantees controllable lift + controllable haul-out + compliant containment.

4) Wire sawing mechanics that actually change cost and schedule

Most marketing explanations of wire sawing skip the mechanics that estimators care about: wire life, corners, attack angle, and water discipline.

4.1 Wire wear as a measurable production metric

A useful budgeting metric is cut area per meter of wire, not just “hours.”

In our field experience with ~10.5 mm sintered diamond wire, a practical planning range is:

- For thicker sections (~400 mm / 16 in and up): ~2.0–2.5 m² cut per 1 m of wire

- For thinner sections (more corner interaction, tighter radii): sometimes closer to ~1.5 m² per 1 m of wire

This is not a universal constant — it depends on reinforcement ratio, embedded steel, corner geometry, water delivery, and pulley layout — but it is a meaningful estimator input because it ties design choices to consumable burn.

4.2 Why corners destroy wire (and how we prevent it)

Corner behavior matters because wire systems do not like sharp changes in direction under tension.

Control measures (work practice controls):

- Chamfer sharp concrete edges before the first pull to prevent bead damage and premature wire failure.

- Hand-pull the wire initially until the kerf “seats” and the wire tracks smoothly.

- Only then run at operational speed/tension.

This is the difference between “wire snapped 10 minutes in” and stable production.

4.3 Attack angle and “glazing” (why production sometimes collapses mid-cut)

If the wire contacts the surface too “flat,” it can polish instead of cut — a phenomenon often described as glazing. Production drops, heat rises, and wear accelerates.

Operational fix: pulley geometry is not static. If cutting rate drops, we adjust pulley positions to restore an effective attack angle and maintain cut efficiency, while balancing water delivery.

5) Water and slurry: the price of dust control

Wet cutting suppresses dust — but it creates slurry.

5.1 The scale is real

On large indoor wire sawing scopes, water usage can be significant (often on the order of ~1.0–1.5 m³ per shift depending on kerf length, cut duration, and water management). Plan for it.

5.2 Slurry is an environmental and facility risk if unmanaged

Concrete wastewater/slurry is highly alkaline. Municipal guidance documents commonly note concrete wastewater can reach pH ~12–13 (comparable to strong household chemicals in alkalinity).

Industry environmental management guidance emphasizes that wastewater contacting cement powder/slurry becomes more alkaline and may require treatment/controls.

Indoor practical system:

- capture liquids with vacuums/containment

- route to approved drains only when authorized by site procedures

- collect solids/sludge into sealed containers for disposal/recycling handling

Estimator takeaway: slurry handling is a labor line item — not a footnote.

6) Verification before cutting: “no-blind-cuts” as an engineering control

Indoor cutting is a risk-transfer problem. You either verify the unknowns up front, or you pay for them mid-cut.

What we verify:

- concealed utilities (where plausible)

- reinforcement layout (to avoid cutting directly into unfavorable bar orientations)

- embedded steel/plates/rails (to anticipate wear and time)

- thickness confirmation in a test zone when drawings are uncertain

Result: fewer surprises, fewer stoppages, better consumable forecasting.

7) Safety in wire sawing: the risk most teams underestimate

Wire sawing is often perceived as “clean and safe.” It is safe when the team treats it like a tensioned cutting system with a defined danger zone.

7.1 Wire guards, danger zones, and entry rules

Operating manuals and safety documents for wire saw systems emphasize:

- do not begin operation unless guards are properly fitted

- treat the wire path as a hazard zone

- only enter the danger zone after the drive is off and the system has stopped.

7.2 Operator positioning: line-of-fire control

A practical indoor control that matters: the operator should not stand in the wire plane. Remote control operation from protected positions reduces exposure if a failure occurs.

Estimator/engineer takeaway: safety is not a slogan; it is a layout decision.

8) Haul-out without excavators: the real indoor playbook

Cutting is phase one. Haul-out is where most schedules slip.

8.1 Tooling and methods

Depending on constraints, segments move via:

- dollies / skates

- pallet jacks

- chain falls and winches

- overhead crane beams

- forklifts/skid steers where permitted

8.2 Route engineering

We plan around:

- minimum width/height clearances

- turn radii in corridors

- elevator capacity and platform geometry

- ramp gradients

- staging nodes (“rest points”) for safe repositioning

Key question: if the segment cannot traverse the tightest route point, the segmentation plan must change — not the other way around.

9) Quantified case snapshots (anonymous, constraint-driven)

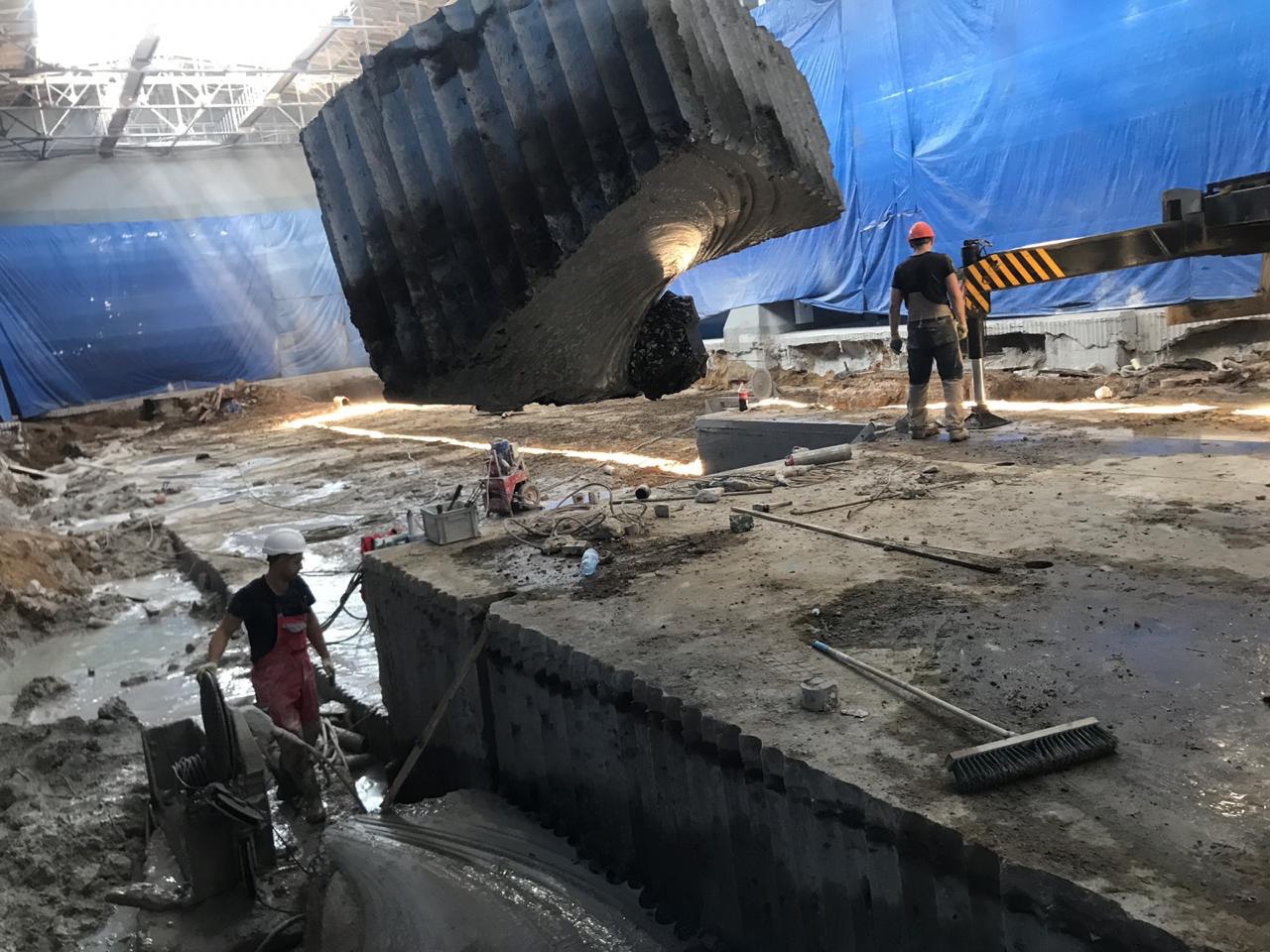

9.1 Industrial node removal (pumping station / structural members)

Scope type: thick slabs + beams/girders + columns in an industrial environment.

Method: wire sawing segmentation + overhead crane beam picks + direct loading to trucks.

Indicative quantities:

- wire saw cutting area: ~200 m² (project memory estimate)

- segment count: ~30 pieces

- total removed mass: ~100 tonnes (order of magnitude)

Outcome driver: lift plan matched to segment weights; haul-out and loading sequence integrated with cutting sequence.

9.2 Data center floor removal (controlled removal with continuous operations nearby)

Constraint: facility operations continued; adjacent work zones active; disruption and unplanned outages unacceptable.

Method: segmentation into manageable pieces, crane beam picks, continuous logistics.

Indicative quantities:

- total removed mass: ~200 tonnes

- outbound logistics: ~30 truckloads

- crew: 7–10 people

- duration: ~20–25 shifts (~1 month)

Outcome driver: logistics-first segmentation, continuous slurry control, and predictable sequence.

Note: these are field estimates intended to illustrate planning logic — exact quantities are project-specific.

10) A practical estimator’s model: how to budget indoor wire-saw segmentation

A useful estimating breakdown is to think in “systems,” not in “tool hours.”

10.1 System 1 — Verification and planning

- site walk + route mapping (tight points, staging nodes)

- test scan / GPR where uncertainty exists

- lift point strategy (anchors vs through-cores vs forks vs crane beam)

- segmentation grid and sequence plan

10.2 System 2 — Cutting production

Cost drivers:

- reinforcement ratio and embedded steel

- thickness (thin sections can increase corner wear)

- number of corners and resets (wire wear + labor)

- water delivery reliability

- pulley layout complexity

10.3 System 3 — Slurry containment and handling

- vacuuming

- containment barriers

- containerization of solids

- authorized discharge procedures (if any)

- cleanup standards

10.4 System 4 — Handling, staging, haul-out, loading

- pick time per segment

- travel time along route

- staging management

- loading cycle time to truck/bin

- floor protection/load distribution if needed

Estimator insight: the cheapest cut is worthless if handling is slow or non-compliant.

11) Pre-bid data request (what a serious estimator should ask for)

If you want a predictable price and schedule, request:

Geometry and structure

- thickness range (or access to test-zone verification)

- reinforcement type (standard vs heavy bar; any embedded steel)

- drawings and photos

Site constraints

- access points, corridor widths, elevator capacities

- working windows (e.g., 00:00–05:00)

- noise/vibration constraints

- dust and water discharge restrictions

Logistics

- where trucks/bins can be placed

- distance from exit to loading point

- staging space limitations

Quality/safety

- containment requirements

- exclusion zones and pedestrian control (common in transit/public sites)

12) Conclusion: why indoor wire sawing is an engineering service, not a “cut”

Indoor controlled demolition in sensitive sites is won by the team that treats the job as a segmentation and logistics system:

- verify unknowns before cutting

- select grid based on lift + route + floor + staging + disposal

- manage wire wear through geometry and work practices

- suppress dust with wet methods and own the slurry problem

- protect workers through defined danger zones and guarded operation

- integrate cutting sequence with haul-out sequence

When those pieces align, wire sawing becomes a predictable, low-disruption method for removing thick reinforced concrete without impact-dominant equipment indoors.

Technical CTA (non-sales, estimator-friendly)

If you’re scoping an indoor removal where impact demolition is restricted, the fastest way to get to a predictable plan is:

- Send drawings + photos + access constraints (tight points, windows, staging).

- We build a segmentation + haul-out plan: grid, pick method, route, staging, loading.

- If thickness/rebar is uncertain, we use a test-zone scan to confirm before committing to production assumptions.

Lets cut straight to the solution Free Quote

Got a project in mind? Need a quote or have a technical question? Our team will get back to you within 1 business day.

Get Your Free Quote

Contact Information

7:00 AM – 8:00 PM Monday to Friday

(647) 558-8505Service Area

Toronto & GTA (500 km radius)

Why Choose DRM?

- Licensed & Insured

- 15+ Years Experience

- Modern Equipment

- 24/7 Emergency Service

Indoor Wire Sawing Without Heavy Equipment — Segmentation & Haul-Out FAQ

Practical answers on how we segment thick reinforced concrete indoors—segment size, weight math, access limits, lift/haul-out tools, slurry control, and safe removal planning.